Machining parts CNC machining precision parts overseas procurement

JAPAN-QUALITY with Chinese & Vietnamese price!

We have expertise for overseas procurement.

Are these some of the problems YOU have?

- Worried about overseas procurement in case of defective products.

- Not getting the products after payment.

-

Getting something different from the drawing.

Don’t worry, and please let us handle your problem!

We can lower the price of the product by 30%. We can also lower the mold price by 50%.

We offer Japan-high-quality products from overseas.

We will get back to you TOMORROW at the earliest, and will manufacture within the minimum of 20 days!

Examples of Products

Stamping

Processing in the press mold is the most advantage of that unit price is very cheap, but that the initial cost of the mold is expensive is the disadvantage.

By switching to overseas procurement, it is also possible to 50% downthan Japan the mold cost.

![]() Details of the press working is here

Details of the press working is here

Cold forging (cold heading)

It is a processing method of mass production orientation.

Is there a problem of tolerance, but the big cost will be possible by changing to cold forging from machining.

Initial cost is suppressed mold cost will be expensive, but you do overseas procurement, cost advantages will appear more.

![]() Details of cold working is here

Details of cold working is here

Carbide processing

It is used in cutting tools, such as molds and parts that are required to wear very hard.

Because of the cost of the wire cut time, the step of polishing, cost reduction is possible in overseas procurement of cheap labor costs.

About 5 days, delivery of goods in a week is also possible in the shortest production with the Shenzhen factory.

![]() Details of carbide processing is here

Details of carbide processing is here

Die-casting

One of the die casting process, die casting is a method of pouring the zinc and aluminum dissolved mainly precision molds. Productivity is suitable for mass production high.

The mold is also a long life can be manufactured in complex shapes than the casting other methods, the mold cost is more expensive than the other casting.

Mold cost can be about 30% down by performing the overseas

![]() Details of the die-casting is here

Details of the die-casting is here

Lost-wax process

Lost wax is characterized by that the mold is less expensive than other methods of casting.

If there is a possibility that the shape changes, it is suitable for production in small lots.

Mold is a cheap product and cost performance is possible processing cost also pressed strongly by performing overseas procurement.

![]() Details of the lost wax is here

Details of the lost wax is here

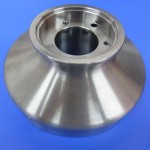

Processing of machining cutting other

Images are processed using a cutting tool to machine NC lathe, a machining center or the like.

It is suitable for the production of medium-lot from a small lot for the initial cost of the mold, etc. is not applied compared with other processing.

It is often considered the production of small lots and not suitable for overseas procurement, the cost benefit is issued even if the small lot (100 ~) If the product number of processing steps in many cases.

mail:web@sakaikinzoku.com

Sakaikinzoku MFG Co.,Ltd

2-20-5 Tennoujicho-kita Abeno-ku Osaka Japan

TEL:+81-66713-6159 FAX:+81-66713-8823

- Questions or consultation , please feel free

-

About us

無料メールマガジン

-

読切メルマガ

失敗のない海外調達3つの方法

⇒詳細はこちら

お問合せ

- SAKAIKINZOKU.MFG.CO.,LTD.

TEL:+81-66718-6007 -

〒543-0044

13-3 Kokubucho, Tennoji-ku osaka-shi, Osaka JAPAN

Mail:eigyo@sakaikinzoku.com

-

読切メルマガ